A Strapping Machine Can Help You Meet Sustainability Goals

Wiki Article

Unleashing the Potential of a Strapping Device in Enhancing Your Workflow

A strapping device might be the answer you have actually been browsing for if you're looking to improve your product packaging performance. These makers can lessen manual work while ensuring your items are safely packaged. With various alternatives offered, finding the best fit for your procedures is necessary. However how do you select the very best one, and what advantages can you truly expect? Allow's check out the opportunities with each other.Comprehending the Basics of Strapping Machines

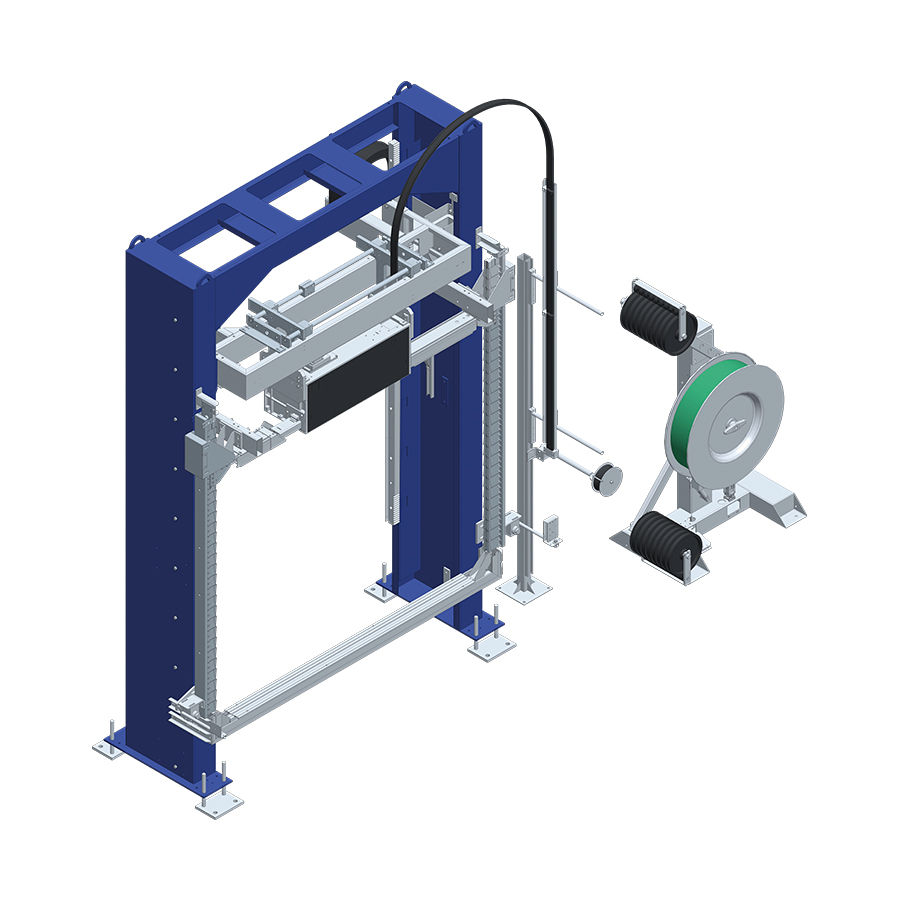

Strapping equipments are crucial tools in product packaging and logistics, developed to safeguard products for secure transport. These equipments utilize numerous materials, like polypropylene or polyester straps, to bundle products with each other (Strapping Machine). You'll locate that strapping equipments can be found in different types, consisting of manual, semi-automatic, and completely automatic designs, each matched for particular functional needs.Understanding how these equipments job is essential for enhancing your operations. They apply stress to the band before sealing it, making certain a limited fit that keeps your things secure during handling and delivery. Acquainting on your own with the components, such as the tensioning mechanism and sealing approach, can aid you choose the best equipment for your organizationKey Benefits of Utilizing a Strapping Maker

You're not simply enhancing your packaging process; you're additionally enhancing efficiency and reliability when you spend in a strapping equipment. These equipments enable for quicker strapping, minimizing manual work and decreasing the danger of mistakes. You'll see a marked decline in time invested on product packaging, allowing your group to concentrate on other crucial tasks.Moreover, strapping devices offer constant tension and secure packages, which aids stop damage during transportation. This integrity brings about fewer returns and improved customer complete satisfaction. Furthermore, utilizing a strapping device can save you cash in the future by minimizing material waste and reducing labor costs.Lastly, they're functional adequate to manage different package dimensions and materials, making them a valuable property in any type of procedure. Embracing a strapping equipment means you're buying a much more streamlined, reliable, and efficient approach to product packaging.

Kinds Of Strapping Machines Available

When it comes to strapping makers, you've obtained options. You can choose between manual strapping makers for hands-on control or automated strapping systems for effectiveness. Each type has its own benefits, making it essential to pick the right one for your demands.

Guidebook Strapping Machines

Although several packaging solutions exist, manual strapping devices attract attention for their simplicity and performance. These devices are ideal for tiny to medium-sized procedures where transportability and flexibility are vital. You'll discover them easy to make use of, requiring marginal training. With a manual strapping device, you can swiftly secure plans making use of polypropylene or polyester bands, guaranteeing your products remain undamaged during shipping.They use a cost-effective remedy without sacrificing top quality, making them optimal for companies on a spending plan. Plus, manual strapping machines are small and can fit in tight spaces, allowing you to enhance your operations. Whether you're in a warehouse or a little workshop, these equipments can greatly boost your packaging process, making your operations a lot more effective and trusted.Automatic Strapping Solutions

Have you considered just how automated strapping systems can reinvent your packaging operations? These equipments offer performance and accuracy that hands-on approaches simply can't match. With alternatives like totally automatic, semi-automatic, and high-speed strapping systems, you can pick the right fit for your production needs. Completely automatic systems simplify the whole procedure, needing very little operator intervention. Semi-automatic makers, while still efficient, allow for a bit more control. High-speed systems deal with high-volume procedures, making sure dependable and fast strapping. By incorporating these systems, you'll not only lower labor prices but additionally enhance product packaging quality. Bid farewell to irregular strapping and hi to consistent, protected plans that boost your operational performance and speed. It's time to step up your video game with automatic strapping options!Factors to Take Into Consideration When Choosing a Strapping Device

Picking the right strapping maker can significantly enhance your product packaging performance, so it's crucial to think about several essential variables prior to deciding. Take into consideration the type of materials you'll be strapping. Various machines are created for steel, paper, or plastic strapping, so pick one that fulfills your needs.Next, think regarding the speed and volume of your operations - Strapping Machine. If you're collaborating with high volumes, an automated strapping equipment might be extra suitable, while a hands-on choice could be sufficient for smaller sized tasks.Don' t fail to remember regarding the maker's dimension and footprint. Ensure it fits your work space without impeding movement.Additionally, try to find functions like adjustable stress and securing techniques to advertise adaptability. Assess your budget, stabilizing ahead of time costs versus lasting effectiveness gains. By thinking about these elements, you'll make a more enlightened selection that aligns with your functional objectivesExactly how to Integrate a Strapping Machine Into Your Operations

To effectively integrate a strapping equipment into your workflow, begin by examining your operational requirements. This aids assure the device fits seamlessly right into your existing processes. As soon as that's established, efficient staff training will certainly be essential to optimizing its efficiency and efficiency.Evaluating Functional Needs

Integrating a strapping equipment right into your process can greatly enhance effectiveness and performance. First, evaluate your existing packaging process. Identify bottlenecks where hands-on strapping reduces you down. Consider the quantity of items you handle everyday and the details requirements for protecting those things. Assess the physical area offered for the equipment to assure it fits perfectly into your operation. Next off, determine the kinds of products you use for strapping, as the device should fit them. It's likewise vital to think of how the device will certainly connect with existing tools and process. By comprehending these functional requirements, you can select the best strapping device that aligns with your goals, eventually causing smoother processes and improved output.

Training Team Properly

While the intro of a strapping maker can simplify your operations, reliable training for your personnel is vital to optimize its benefits. Begin by providing hands-on presentations to acquaint every person with the equipment's attributes and features. Urge your group to ask concerns and share their issues. Produce an user-friendly manual or quick-reference overview to strengthen training and function as a source. Arrange regular refresher course courses to maintain skills sharp and address any type of updates or changes. Additionally, assign an advisor or skilled operator to sustain new group members as they adapt. By buying your personnel's training, you'll not only enhance their confidence but additionally improve performance, making certain the strapping click maker ends up being an important part of your operations.Maintenance Tips for Optimum Strapping Device Efficiency

Preserving your strapping equipment is crucial for making sure constant efficiency and longevity. Begin by frequently examining and tightening any kind of loose bolts or screws to stop vibrations that can create wear in time. Tidy the device daily, getting rid of dust and debris that can influence its efficiency. Lube moving components as recommended in the manufacturer's guidebook, making certain smooth procedure and minimizing friction.Monitor the strapping stress and readjust it according to your material specs, as inappropriate tension can cause product damages or lost materials. Strapping look at this now Machine. In addition, evaluate the strapping product for any indications of wear or damages, changing it as required to avoid disruptions in your workflow.Finally, timetable routine professional maintenance to capture prospective problems before they become major problems. By adhering to these upkeep tips, you'll keep your strapping equipment running efficiently, boosting your operations and prolonging its lifespanReal-World Success Stories of Strapping Device Application

After ensuring your strapping device runs properly, it's time to discover just how organizations have actually efficiently harnessed this modern technology. Take, as an example, a packaging company that fought with inconsistent strapping. After executing a modern strapping machine, they saw a 30% rise in throughput and a substantial decrease in product waste.In an additional instance, a furnishings supplier used strapping machines to secure items for shipping. This not only quickened their packaging process but also reduced damages during transportation, causing happier customers.Similarly, an e-commerce service incorporated strapping machines into their procedures, enabling them to successfully pack items and reduce labor costs.These success tales highlight just how spending in a strapping machine can dramatically boost your functional efficiency, cut prices, and boost client contentment. By picking up from these instances, you can better imagine how this technology can change your own organization processes.Regularly Asked Concerns

Can a Strapping Maker Take Care Of Different Materials and Sizes?

Yes, a strapping equipment can handle different products and sizes. You'll discover versions made to fit various strap widths and densities, ensuring adaptability for your packaging needs and improving performance in your operations.What Is the Typical Lifespan of a Strapping Equipment?

The ordinary life-span of a strapping device typically ranges from 5 to 10 years, relying on use and upkeep. Normal maintenance and proper care can aid you maximize its sturdiness and performance with time.Are There Security Functions in Modern Strapping Machines?

Yes, contemporary strapping devices come with numerous security functions, like emergency stop buttons, protective guards, and sensors that avoid operation when parts are improperly placed. These improvements aid assure your safety while utilizing the equipment.Just How Much Training Is Needed for Operators?

You'll require minimal training for operators, normally a few hours to a number of days, relying on their experience. Most equipments feature straightforward user interfaces, making it simple for your group to adjust quickly.Can Strapping Machines Be Rented Rather of Bought?

Yes, you can lease strapping devices rather than acquiring them. Leasing frequently provides adaptability, lowering ahead of time expenses while allowing you to update devices as needed. It's a clever alternative for handling your useful site operational budget plan effectively. You'll locate that strapping equipments come in different types, including guidebook, semi-automatic, and completely automated models, each matched for certain functional needs.Understanding how these equipments job is crucial for optimizing your operations. When you invest in a strapping machine, you're not simply enhancing your packaging process; you're additionally improving effectiveness and dependability. You can pick between hand-operated strapping makers for hands-on control or automatic strapping systems for performance. If you're functioning with high volumes, an automated strapping maker may be more ideal, while a hands-on choice might be sufficient for smaller sized tasks.Don' t neglect about the equipment's size and impact. After implementing a modern-day strapping maker, they saw a 30% rise in throughput and a substantial decrease in material waste.In one more instance, a furniture manufacturer used strapping machines to secure products for shipping.Report this wiki page